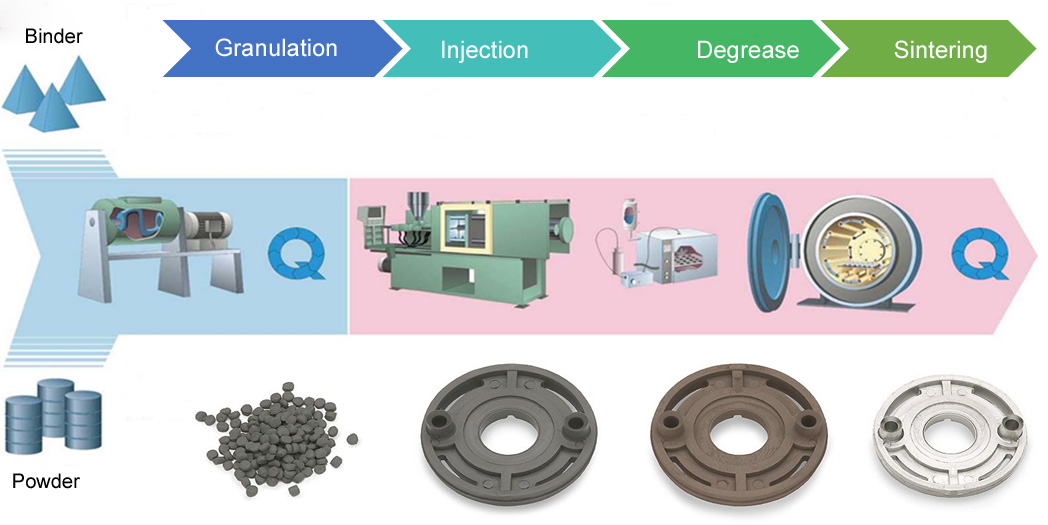

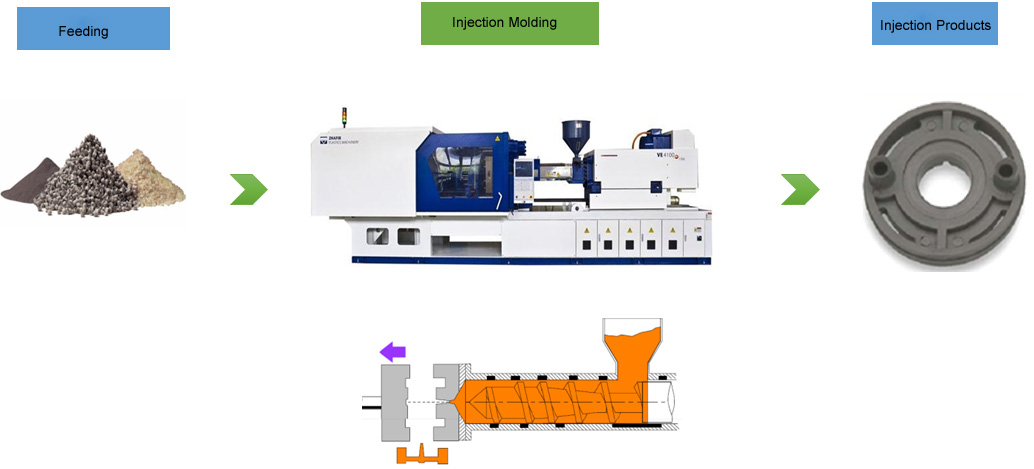

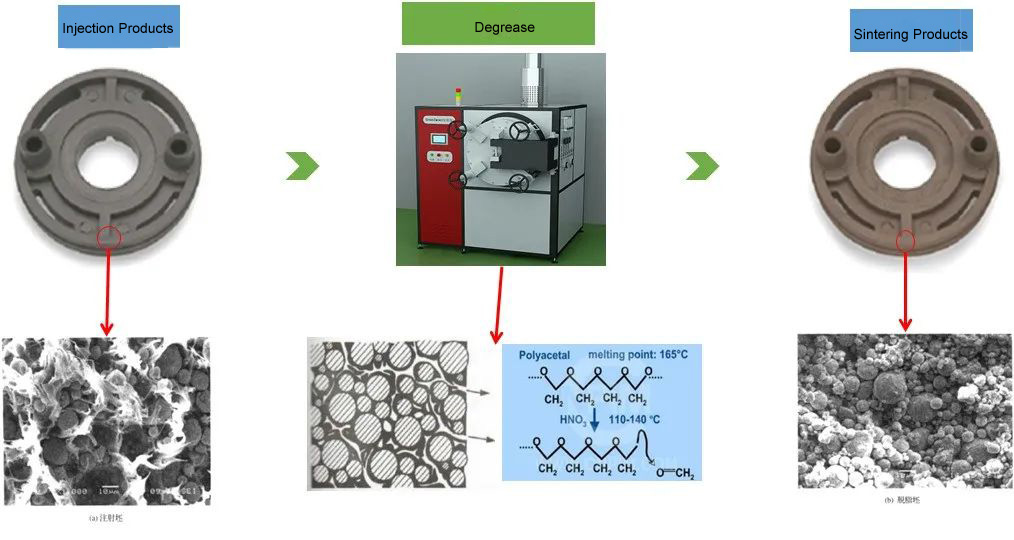

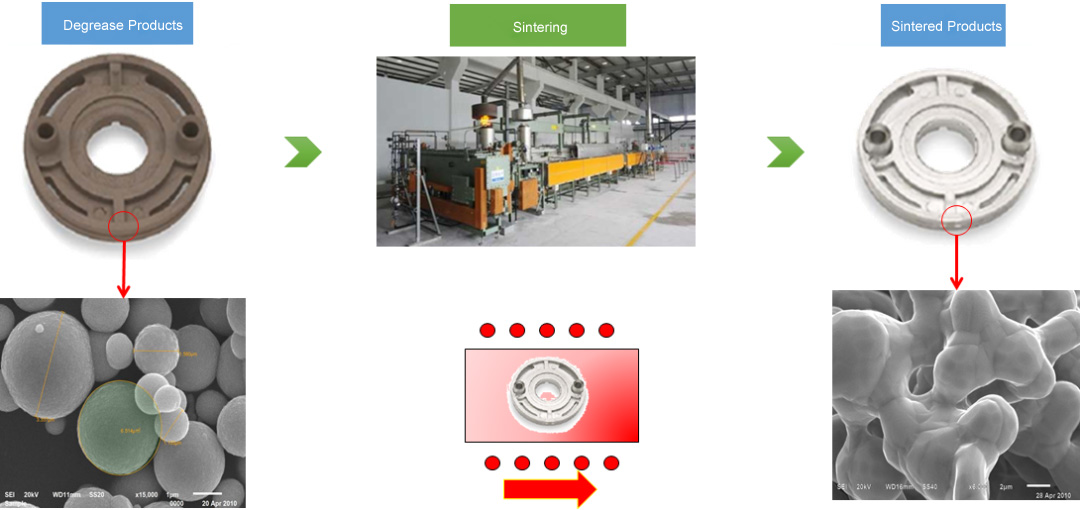

Metal powder injection molding (MIM) is a method of mixing metal powder and adhesive for injection molding. The injection molded products will be degreased and sintered to remove the binder, so as to obtain the metal products we want. The products will be more perfect through subsequent shaping, surface treatment, heat treatment, machining and other methods.

MIM technology introduction

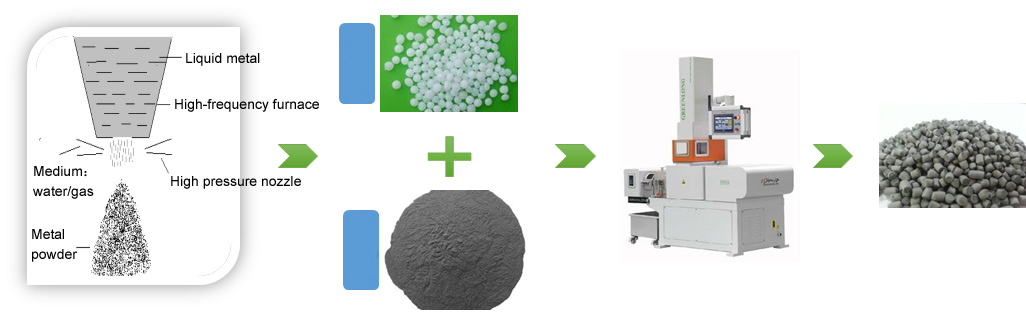

Most manufacturers use the raw material provided by BASF, and a few manufacturers or special material are self prepared.

There are two main types of binders: wax based system and plastic based system.

Key control points: particle size, morphology, carbon and oxygen content, MFI

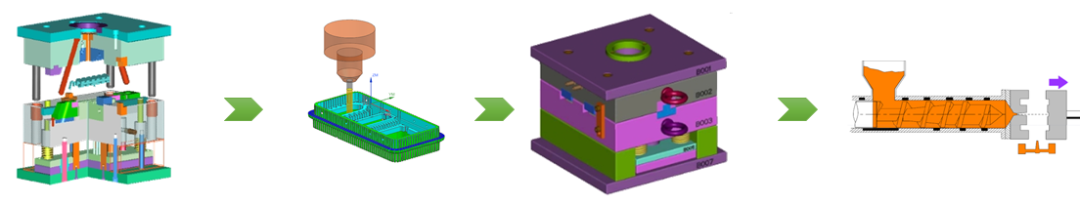

The mold process includes design, processing, mold matching and testing

Key control points:Strength, accuracy, filling balance, air-out, appearance guarantee

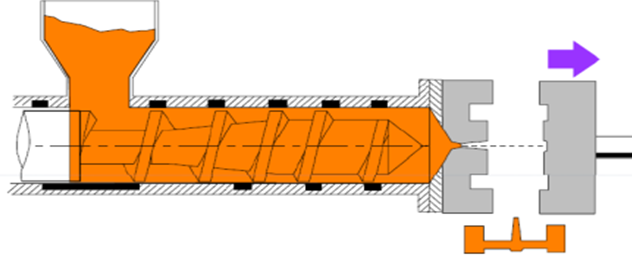

Key points of control: injection temperature, velocity, pressure, product density, appearance, stress and fullness

Key control points: degrease speed, degrease rate and item appearance

Key control points: sintering process, product performance and product appearance